Dal 1981 progettiamo e realizziamo macchine speciali per la General Industry. Un’esperienza di crescita continua, condivisa con i nostri clienti e consolidata grazie a partnership durature e ad una collaborazione intensa in tutte le fasi del processo: dall’analisi dei requisiti all’avvio degli impianti presso il cliente.

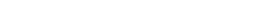

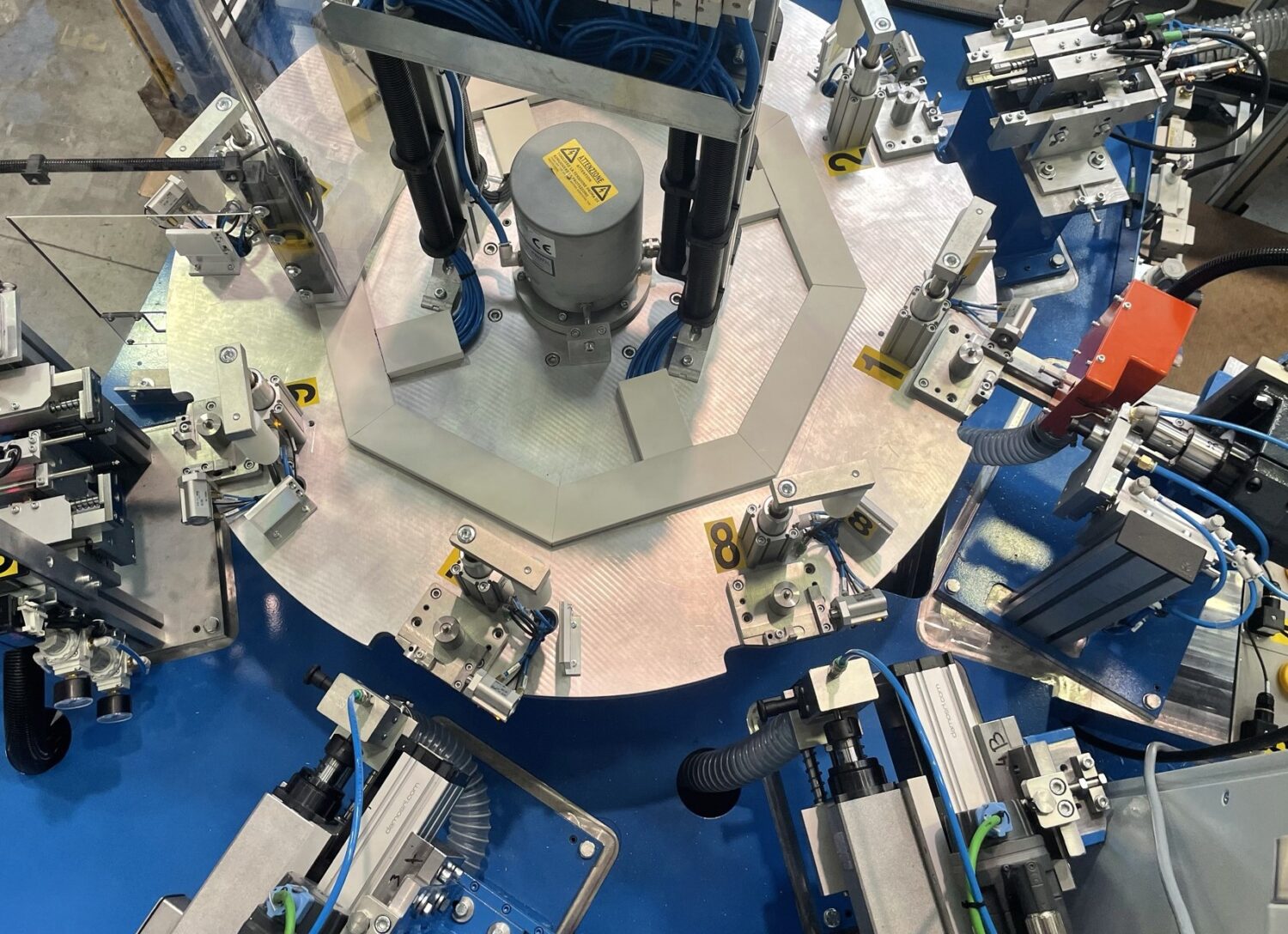

Rispondiamo a ogni esigenza di automazione con soluzioni totalmente personalizzate, frutto dell’unione tra il know-how tecnologico avanzato dei nostri dipartimenti e l’esperienza specifica del cliente. Nascono così macchine e automazioni innovative con elevati standard di affidabilità e sicurezza, perfettamente integrabili con impianti e sistemi informatici esistenti, adatte alle più specifiche applicazioni.

Puntiamo all’innovazione e al miglioramento continuo, integrando le più recenti tecnologie e tendenze dell’Industria 4.0 nelle nostre proposte.

Inoltre, rivolgendo sempre uno sguardo al futuro, ci prepariamo alle sfide emergenti dell’Industria 5.0 e sviluppiamo soluzioni che siano sostenibili, nel pieno rispetto delle normative vigenti e delle aspettative del mercato globale.

AUTOMOTIVE

Soluzioni sviluppate per questo settore:

- assemblaggi;

- controlli dimensionali e qualitativi.

- incollaggi;

- lavorazioni meccaniche;

- trattamenti di plasmatura per componenti plastici;

- saldature.

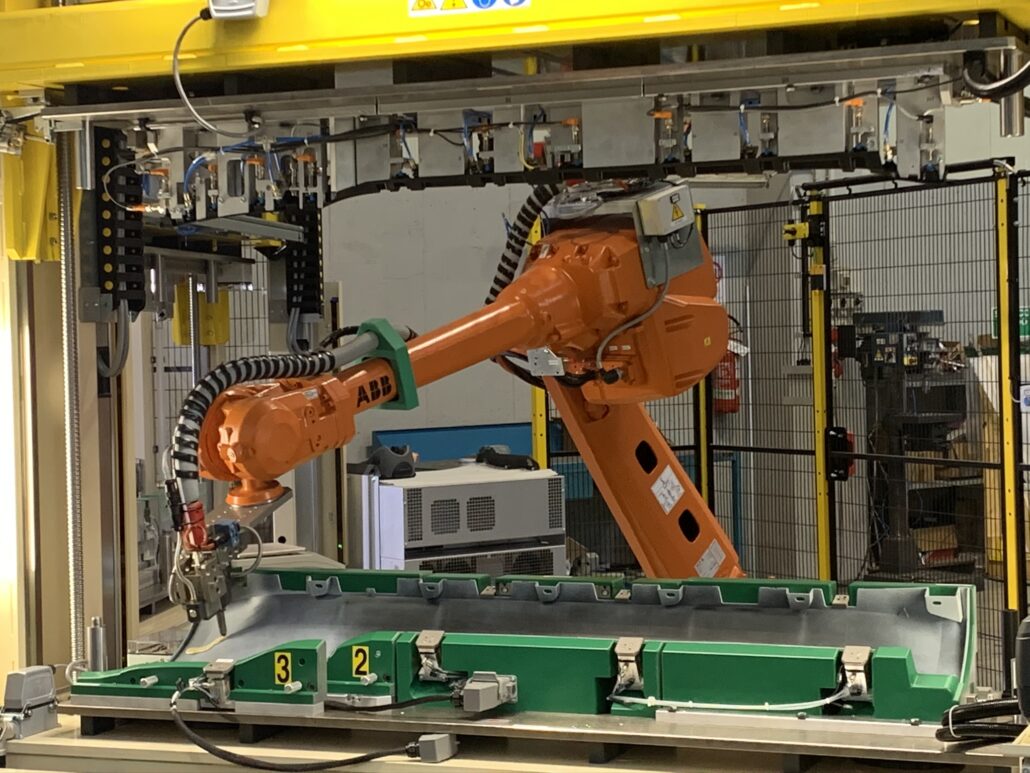

ELECTRICAL AND ELECTROMECHANICS

Soluzioni sviluppate per questo settore:

- assemblaggi;

- collaudi;

- lavorazioni meccaniche;

- saldature.

CONSTRUCTION

Soluzioni sviluppate per questo settore:

- sistemi di fresatura per materiali isolanti;

- sistemi di incollaggio per pannelli sandwich;

- linee di imballaggio per pannelli isolanti.

FURNITURE ACCESSORIES

Soluzioni sviluppate per questo settore:

- assemblaggi;

- collaudi;

- lavorazioni meccaniche;

- saldature.

COSMETIC & MEDICAL

Soluzioni sviluppate per questo settore:

- assemblaggi;

- collaudi;

- dosatura.