Glueing Systems

The automatic glueing systems enable the large-scale production of mated panels, ensuring a high degree of repeatability, accuracy in the application and dosing of the adhesive, as well as maximum precision in the mating process for a high-quality end product.

The solutions are achieved by highly technological systems that can be adapted to plenty of fields of application.

Each gluing system is designed according to the level of automation required, the type of adhesive used, the materials employed, the production capacity required and the specific application requirements. The layout is designed according to the available space and to be interfaced with existing machines.

Main features

- Wide range of processed insulation materials, such as EPS, XPS, PIR/PUR and mineral wools.

- Possibility of creating panels for the most varied construction applications, such as floor insulation, interior walls and roof surfaces.

- Repeatability in glue application and dosing.

- Maximum precision in panel mating.

- High level of automation.

- Very high reliability, designed for high production volumes.

APPLICATIONS

MATED PANELS

In this type of application, the solutions studied allow the mating of two different materials, an insulation panel combined to a structural board, in order to create specific tailor-made panels.

SANDWICH PANELS

In this type of application, the solutions studied allow the mating of an insulation panel between two structural boards, such as OSB or wood, in order to create tailor-made panels for specific applications.

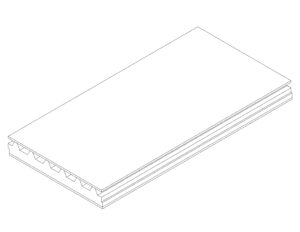

VENTILATED ROOFS

In this type of application, the solutions developed allow the assembly of special panels where the profiled insulation material is combined to one or two structural boards for the creation of ventilated roof surfaces.