Milling Systems

The automatic milling systems enable the production of profiles, sheets and components that require complex processing, while maintaining a high degree of accuracy in terms of surface finish and tolerance compliance.

The machining is carried out in different ways, depending on the final product to be manufactured and the materials used: expanded polystyrene (EPS), extruded polystyrene (XPS), expanded polypropylene (EPP), expanded polyethylene (EPE), and polyurethane (PUR/PIR).

The tools used are designed to obtain material waste with a bead size suitable for reuse as recycled material.

Each milling system is designed according to the type and production capacity required. The layout is designed according to the available space and to be interfaced with existing machines.

Main features

- Excellent surface finish and high accuracy in the final products, thanks to precision mechanics.

- High level of automation, thanks to the use of robots, automatic tool changers and dedicated loading and unloading systems.

- Extremely high reliability, designed for high production volumes.

- Maximum flexibility in terms of sizes and processed materials.

SYSTEMS FOR SHIP LAP JOINTS / PANELS

For this specific application, the milling systems, both as stand-alone and as integrated into new or existing lines, involve the use of milling cutters installed on high-speed electric spindles. These solutions offer higher performance and greater precision compared to hot wire solutions. Each system is integrated with automated material loading and unloading solutions.

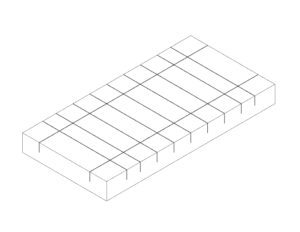

STRESS RELIEVING SYSTEMS

For this specific application, the milling systems, both as stand-alone and as integrated into new or existing lines, use adjustable rotating blades to make cuts on the surface in order to stress relieve the material. Thanks to the use of vacuum belt conveyors, we guarantee a finished product without the imperfections generated by common conveyor systems. Each system is integrated with automated material loading and unloading solutions.

SPECIAL APPLICATIONS

Designed and manufactured according to specific applications, each milling system is conceived based on the complexity of the processing operation to be performed and the required production output. The layout is designed according to the available space and to be interfaced with existing machines.