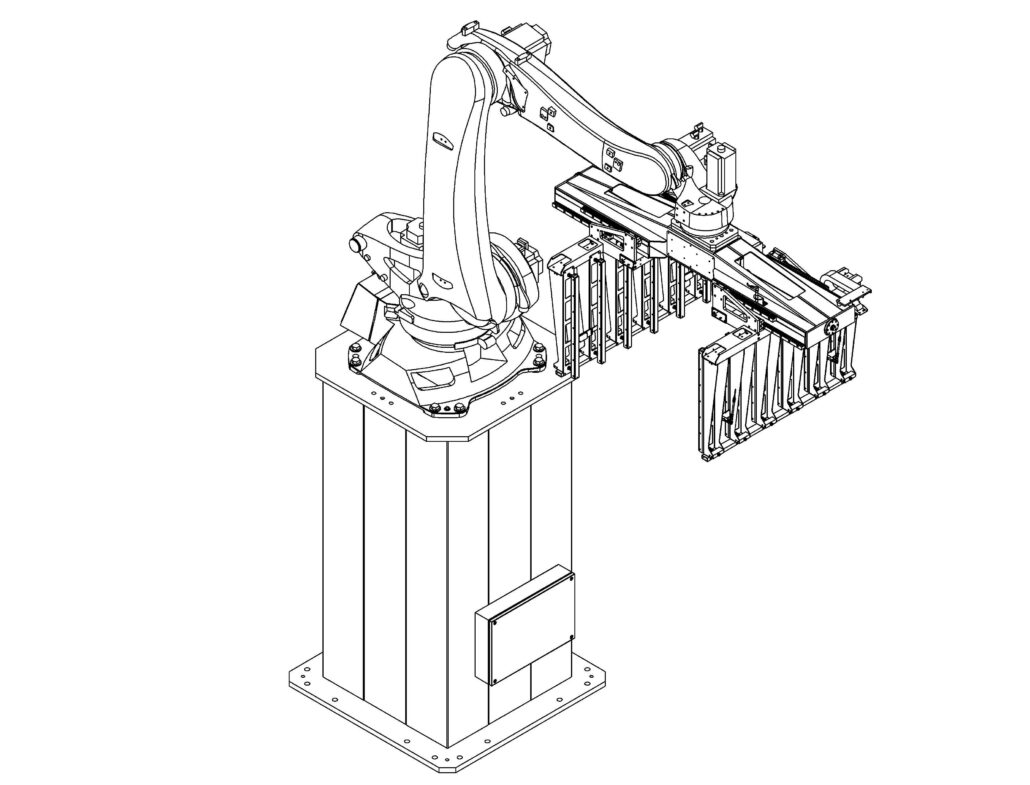

Packing lines

The packing units are fully automatic, installed downstream of the production lines and used for the packing of insulation boards manufactured in different materials such as EPS, XPS, PUR/PIR and mineral wool.

These equipments enable automatic packing, labelling and palletizing of finished products, increasing the production capacity of production lines.

Each packing line is designed according to the type and capacity of production required. The layout is designed according to the available space and to be interfaced with existing machines.

Main features

- Full tracking of the products, thanks to labelling and identification systems.

- Supervision and control fully integrated with Tecnodinamica processing machines.

- High reliability, designed for large production.

- Maximum configuration flexibility.

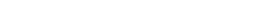

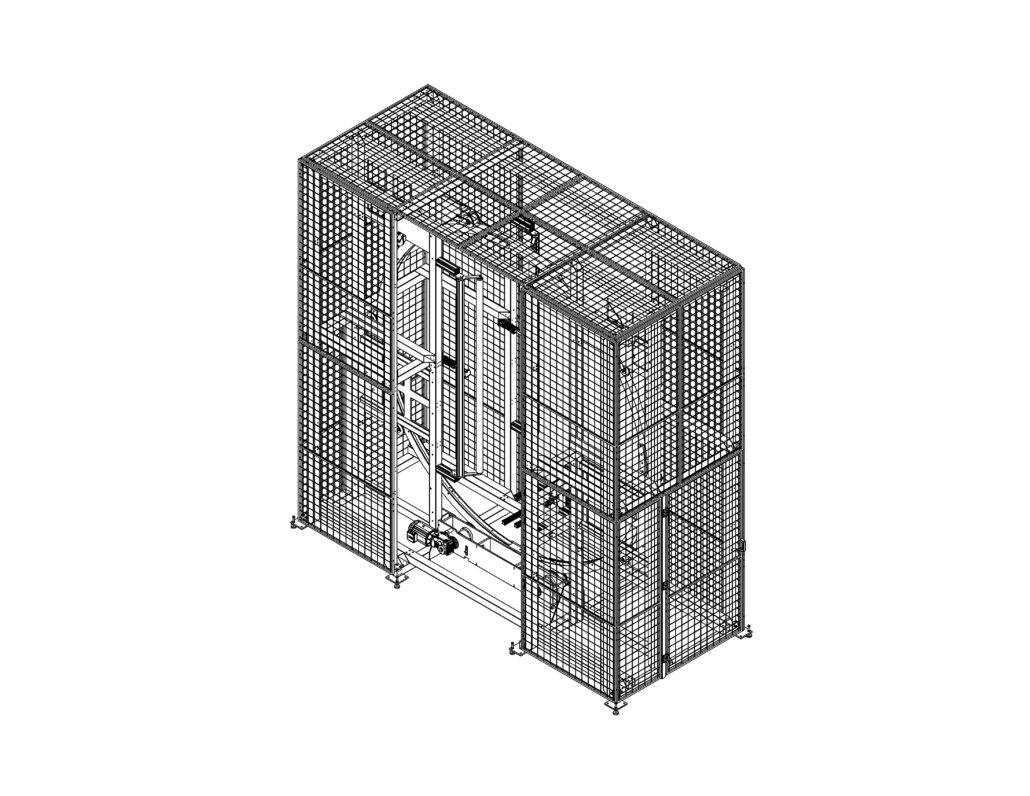

DE-STACKING / STACKING STATIONS FOR PACKS

The pack forming stations are designed and manufactured according to the specific application, their function is a valid alternative to the use of robots for de-stacking the material, the formation of packs with variable height appropriate to the packaging and the composition of the final stack. Depending on the type of material to be handled, pneumatic grippers are equipped to ensure a perfect gripping of the material.

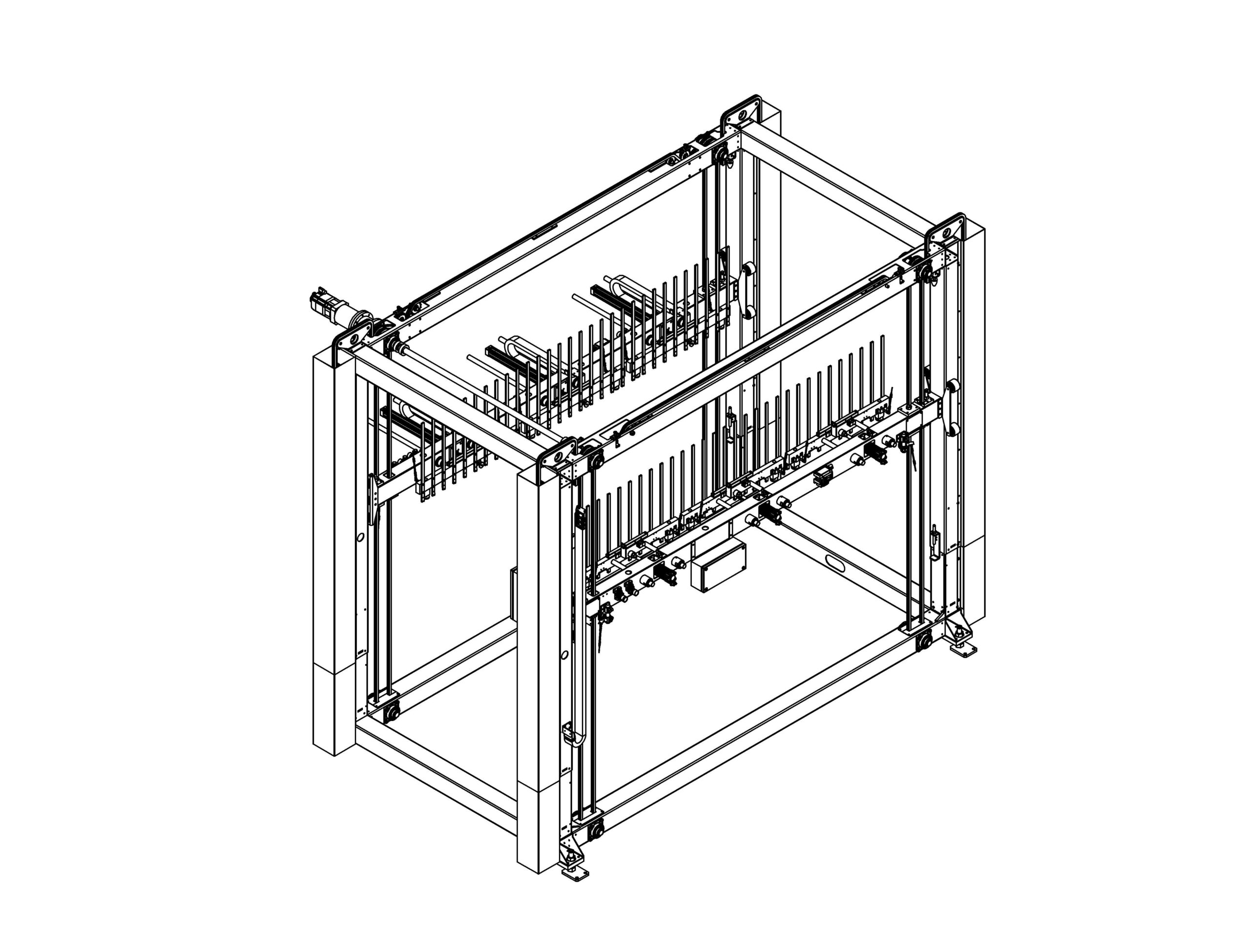

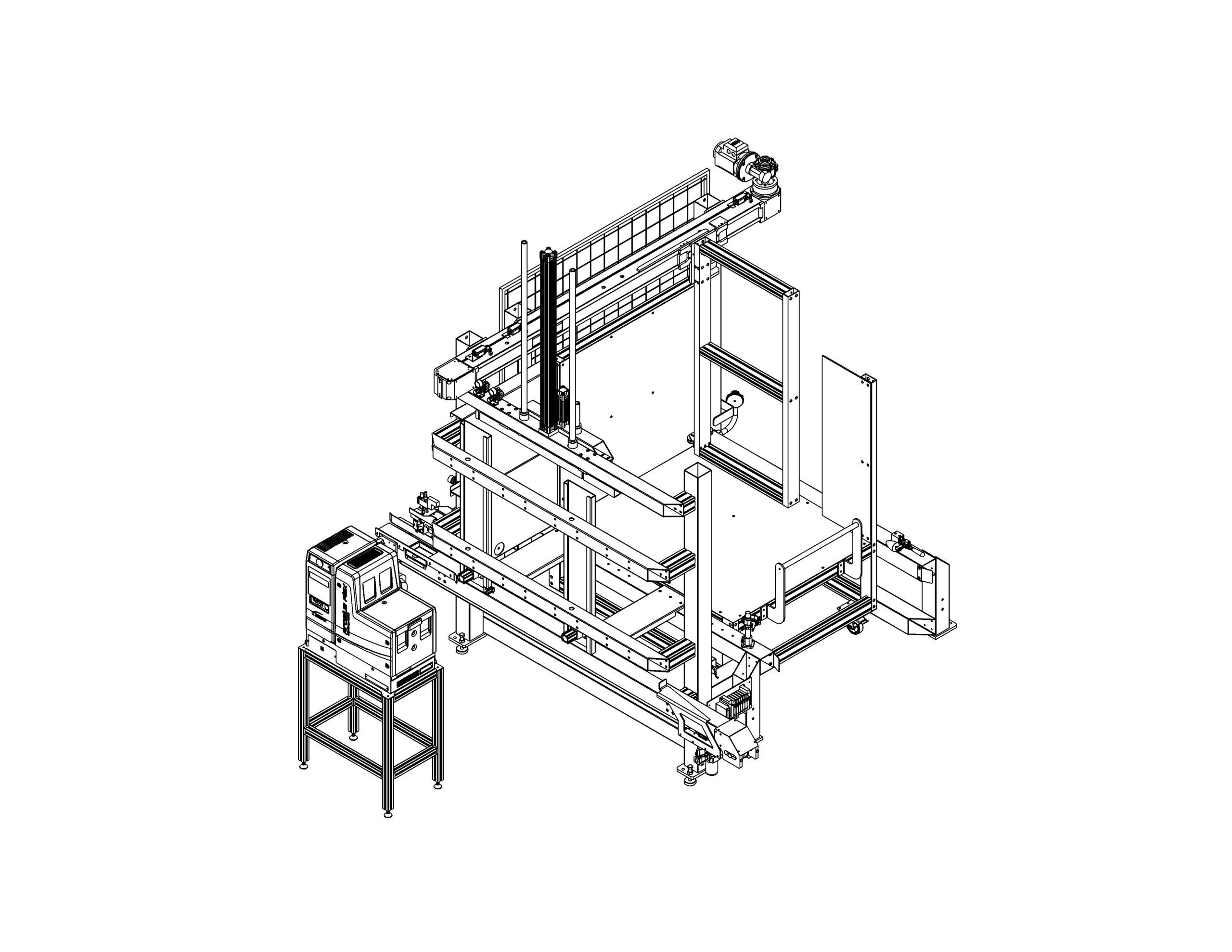

PALLETIZING ROBOTS

A very flexible solution that allows any product to be handled in various formats while ensuring short cycle times. It is used in layout configurations where the robot has several functions, such as: de-stacking of the material with management of variable thicknesses, formation of packs with variable height adapted to the packing, composition of the final stack according to the dimensions and configuration specified as well as feeding of the support pallet of the final stack. Depending on the type of material to be handled, robots are configured to ensure a perfect gripping.

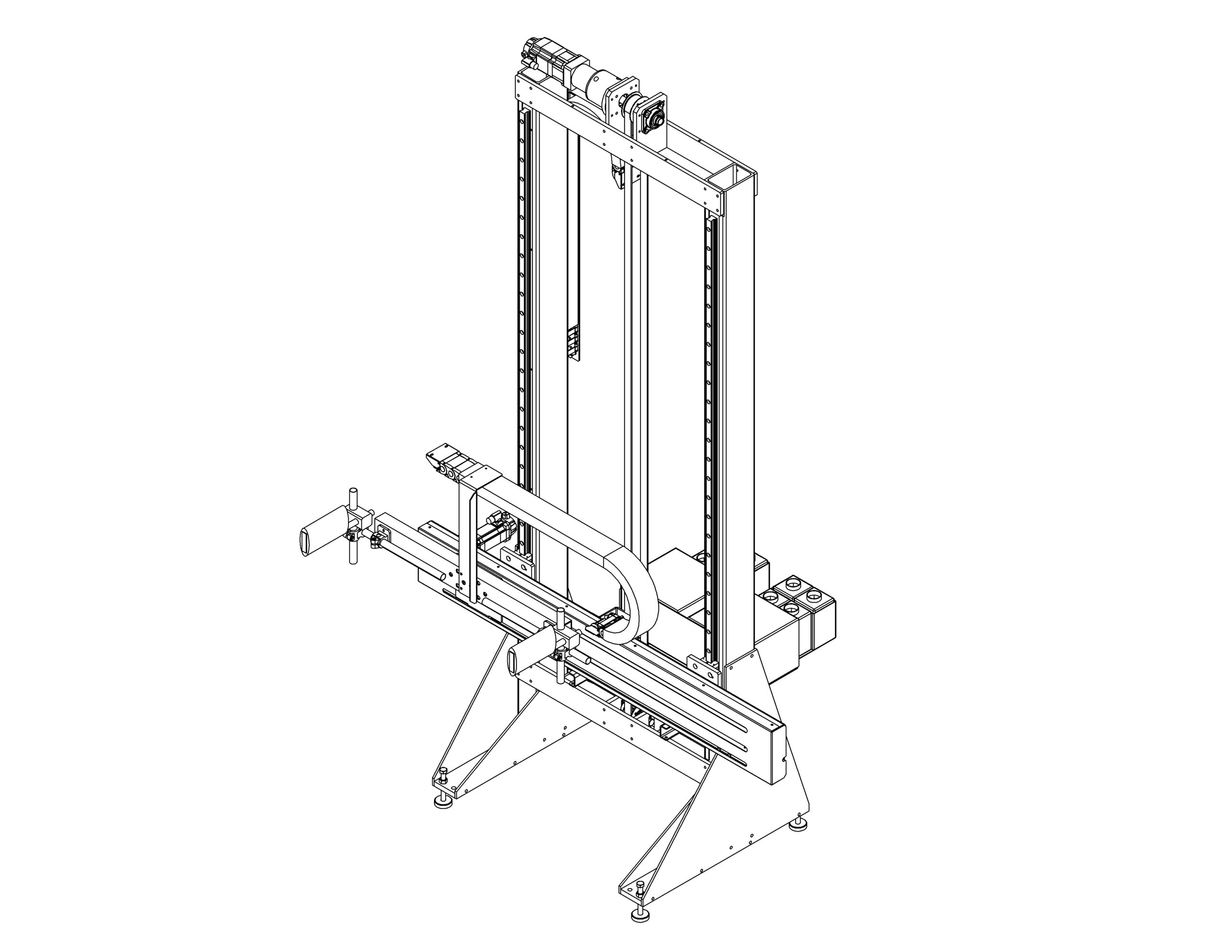

PACK WRAPPERS

The TECNODINAMICA range of pack wrappers are crucial for the production speed of the complete line, they allow the handling of any format while keeping the product very stable. The packs are wrapped with stretch film on 4 or all 6 sides, ensuring maximum protection for the wrapped material.

STACK WRAPPERS

The wrapping machines, conceived to wrap the entire stack, can be orbital or with rotating arm, both models guarantee high production speed. They can be easily integrated into existing lines.

SHEET MARKING SYSTEMS

Ink-jet marking unit for sheet identification with production or product data. The printing head is installed on linear systems, driven by brushless motors, which guarantee vertical and horizontal movements with no margin for error. The print formats can support texts with different font sizes and configurations.

PACK LABELLING SYSTEMS

Unit for automatic printing and label application on packs. The system is designed to ensure accurate and fast labelling, which can also be integrated into existing lines. The label can be configured according to material identification requirements. The system allows label application with the packs in motion.

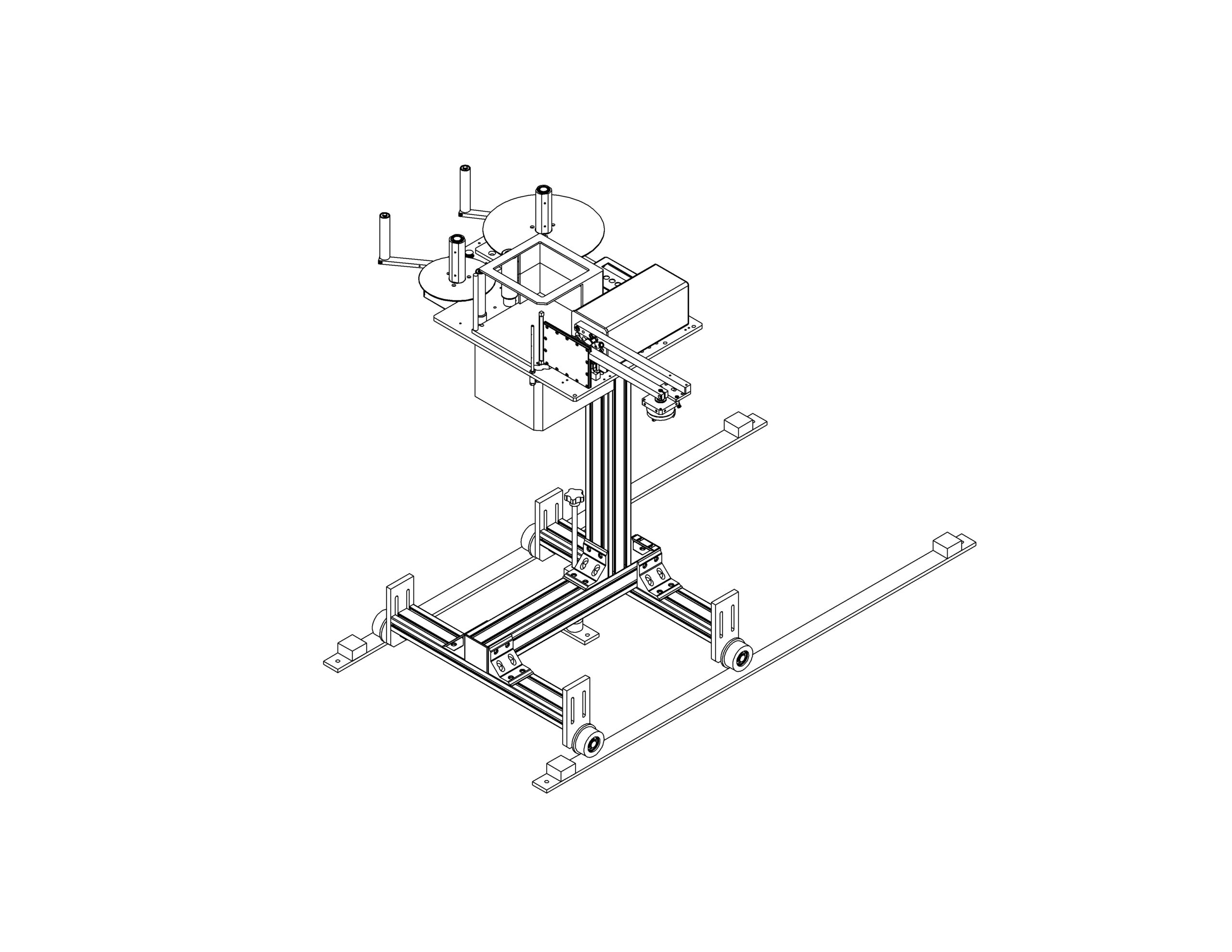

SYSTEM FOR FEEEDING THE BASE SUPPORT OF THE STACK

Automatic unit for feeding and positioning the base support of the final stack to facilitate the handling of the finished product. Depending on the type of material, the system can provide for the application of two or more skids at the base of the stack or the handling of wood/plastic pallets.