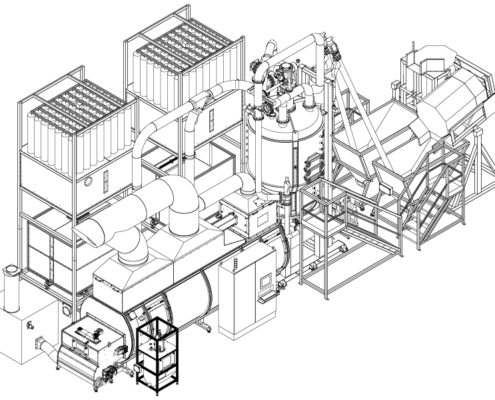

EPS PRE-EXPANDERS

Pre-expanders are automatic machines for expanding polystyrene beads (EPS).

Main features

- Efficiency: constant quality and repetitiveness of the material (+/-0.5%).

- Uniform distribution of steam thanks to the unique design of the expansion chamber.

- Fast material drying guaranteed to the uniform air distribution inside the fluidized bed.

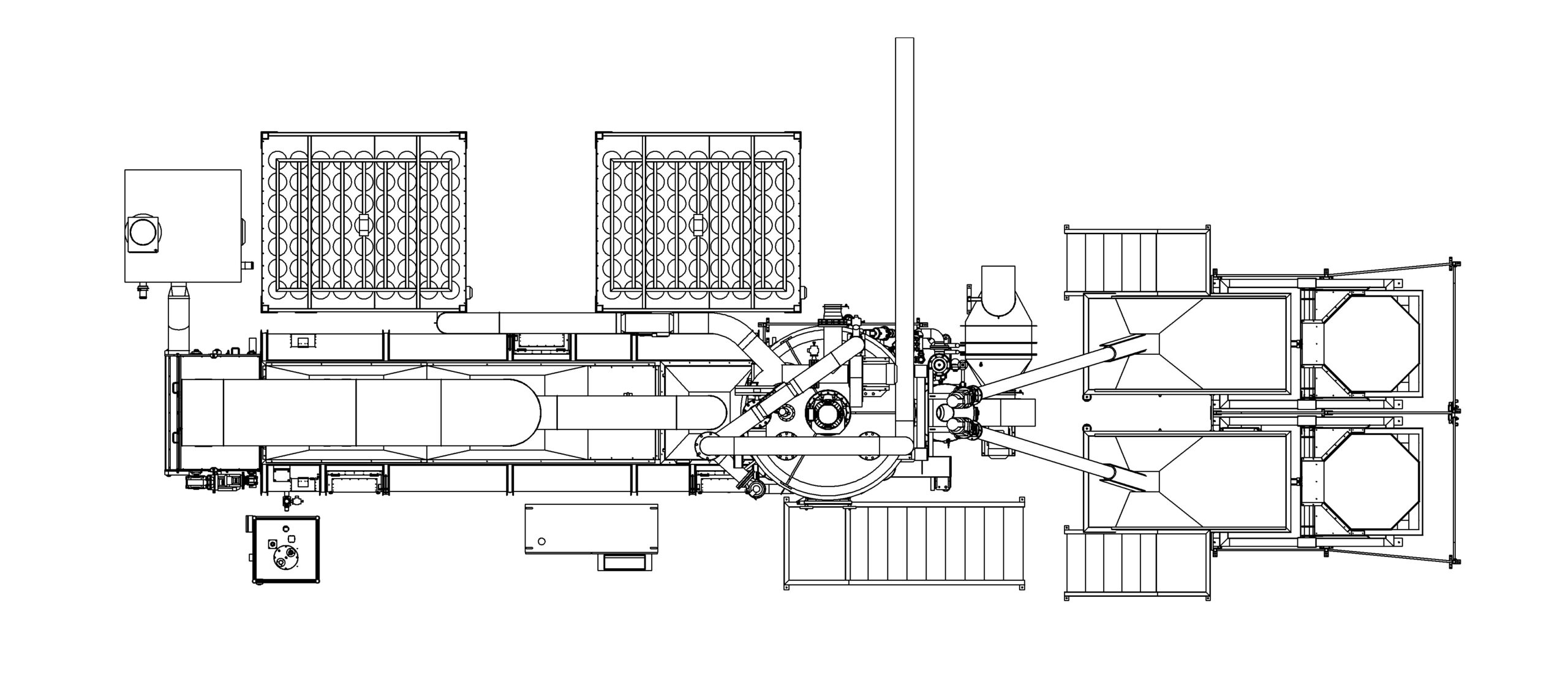

Continuous Pre-expanders

These machines expand polystyrene by means of continuous cycle operations and they allow to achieve bead densities between 40g/l and 15g/l in the first expansion.

These machines can be integrated with second expansion unit in order to achieve lower densities up to 10g/l.

Optionals

- Second expansion unit.

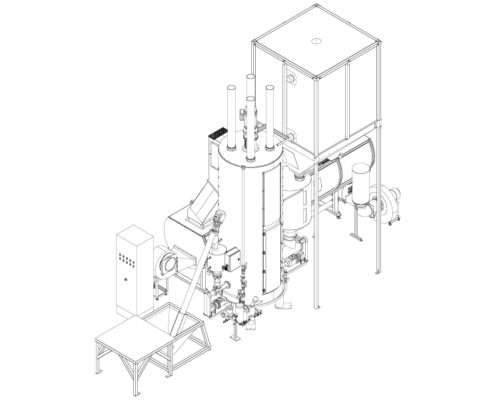

Batch Pre-expanders

EPS beads expansion is performed in batches in order to obtain maximum uniformity of material density.

Process repeatability is ensured thanks to the fully automatic density control system.

Batch pre-expanders allow to achieve, in first expansion, densities between 100g/l and 12g/l.

These machines can be also integrated with a second expansion unit in order to achieve lower densities up to 8g/l.

Optionals

- Octabin tilter.

- Double feeding system.

- Device for colored EPS production.

- Second expansion unit.

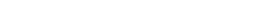

- Pentane gas recovery system.

- Industry 4.0.