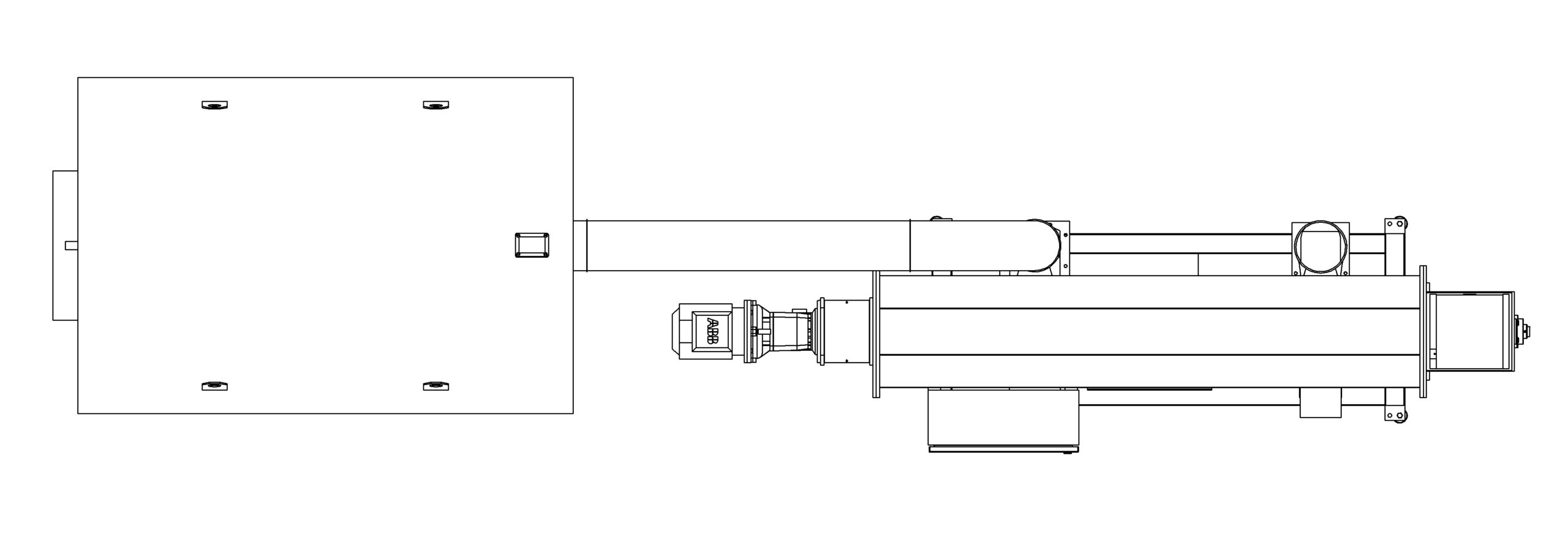

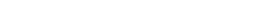

Deduster machine for EPS

We are manufacturers of de-duster machines for EPS recycling, these machines allow to separate granulated material from dust after being processed by granulators.

Main features

- Total dust removal by means of sleeve filters.

- Thermal detector preventing fire ignition inside dust filters.

Granulated material is conveyed by a motorized bristle screw feeder through a suction filter cylinder which separates it from dust.

Dedusted beads are then poured again into a silo by means of a fan, while the dust is retrieved by a sleeve filter.

Optionals

- Dust filters.

- Dusts compactor.

1

2