MACHINES WITH ABRASIVE WIRE

Machines to produce profiles and straight panels in a wide range of materials, such as: rock wool, phenolic resin, rigid expanded polyurethane (PIR/PUR), extruded and expanded polystyrene (XPS/EPS). The cutting is performed by an abrasive wire rotated at high speed.

These machines can be installed in-line with other Tecnodinamica systems for the loading, unloading and packing of the material, in order to deploy fully automated lines.

Main features

- Accuracy and efficiency, as in the best Tecnodinamica tradition.

- CAD software to create and modify the cutting wire path. It supports DXF files import and BITMAP vectorization.

- Supervision system with graphic preview of profiles to be processed and real time control of the machine status and all the machine parameters.

- Auto-recovery of latest working point in case of power interruption (eg. Black-out).

- Broken wire detection system with automatic stop of the machine.

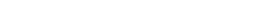

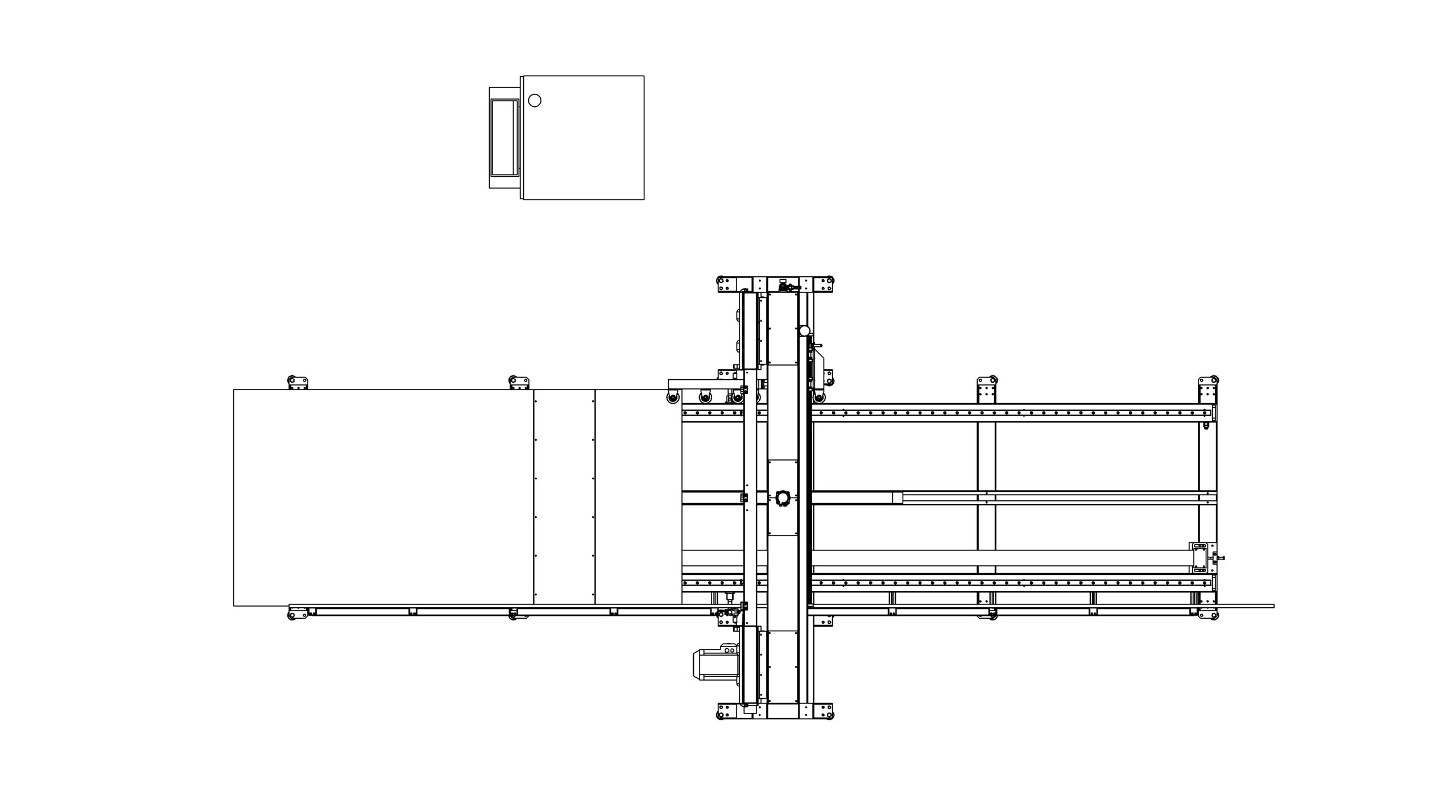

CONTOUR CUTTERS ON TABLE WITH HORIZONTAL WIRE

Contour cutters on table with horizontal wire are the ideal solution for stand-alone installations, where the machine is fed manually and the processed material don’t have to be transferred automatically to other units or machines.

These contour cutters are characterized by a sliding table, with horizontal movement, and a frame with vertical movement holding a wire placed horizontally. The interpolation of the two movements allows to produce straight panels and profiles.

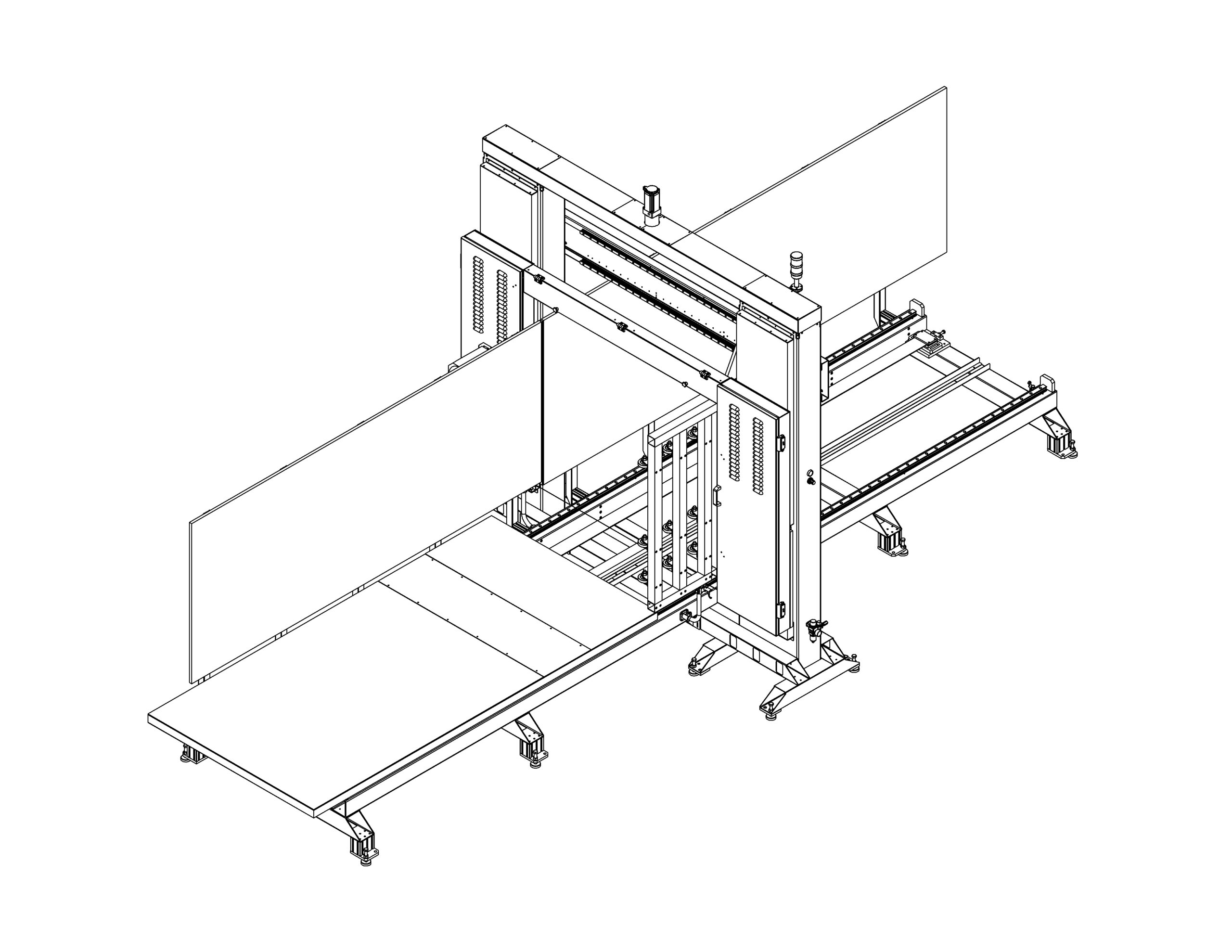

CONTOUR CUTTERS ON BELT WITH HORIZONTAL WIRE

Contour cutters on belt with horizontal wire are suitable to be installed as stand-alone machine as well as in-line with other units or machines.

These machines are characterized by a belt conveyor and a frame with vertical movement holding a wire placed horizontally. The interpolation of the two movements allows to produce straight panels and profiles.

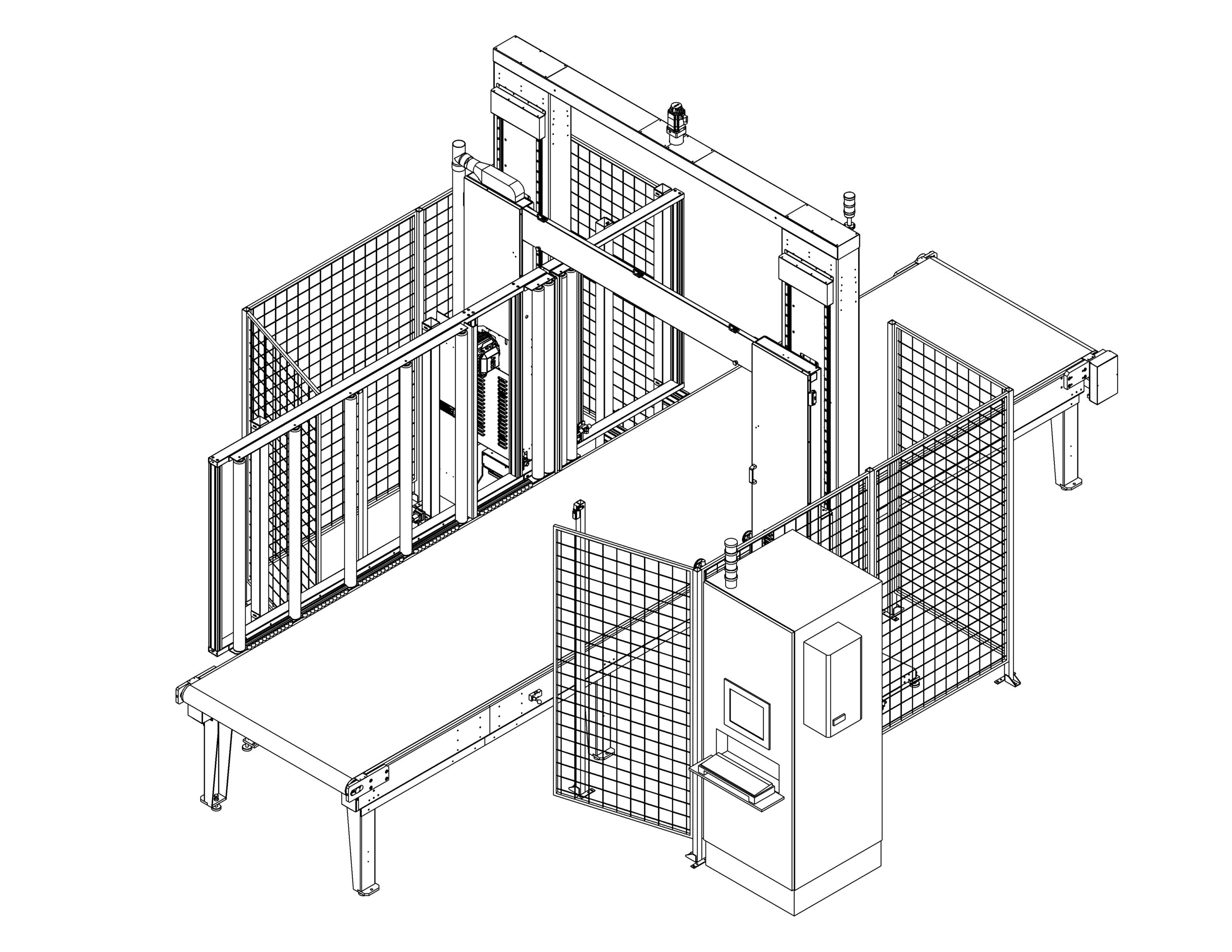

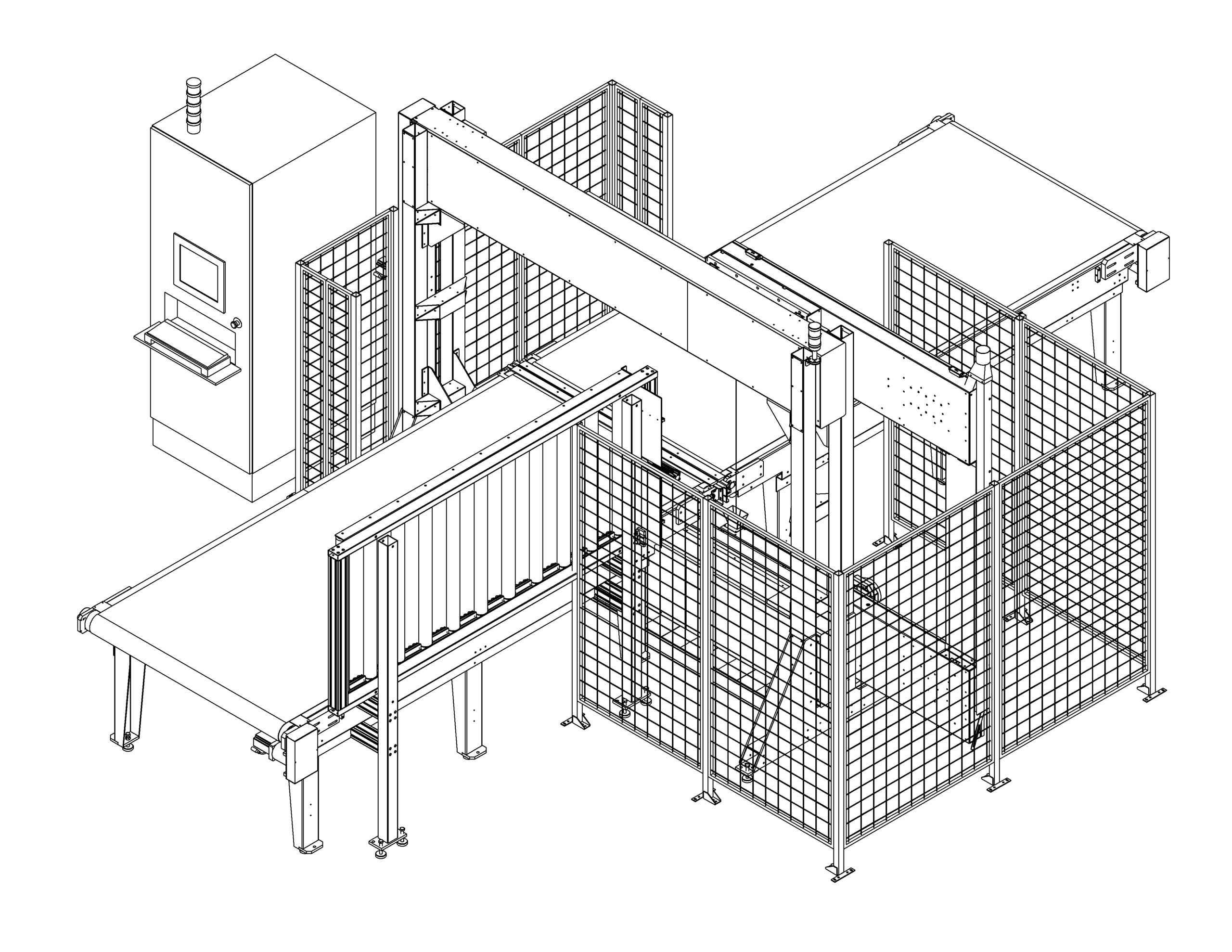

CONTOUR CUTTERS WITH VERTICAL WIRE

Contour cutters with vertical wire are suitable to be installed as stand-alone machine as well as in-line with other units or machines.

These machines are characterized by two belt conveyors and a frame with horizontal movement holding a wire placed vertically. The interpolation of the two movements allows to produce straight panels as well as profiles. Thanks of the two belt conveyors, these machines are also suitable for all those processes where there is the need of using the machine as a guillotine.

Options

- Upper pressing units.

- Wire guiding unit.

- Wire cleaning unit.

- Industry 4.0.

Upper pressing units. Pneumatic back pressure system to steady the material during the cutting phase. This system allows to get a better cutting quality with some specific materials, such as XPS.

Wire guiding unit. This unit is suitable when cutting products where thicknesses with very narrow tolerances are required.

Wire cleaning unit. Unit for cleaning the wire in order to increase its lasting and performance. The unit is suitable when cutting some specific materials, such as containing adhesives or glues.

Industry 4.0. Connection of the machine to third parties softwares, such as ERP and MES, by exporting process data to SQL database.