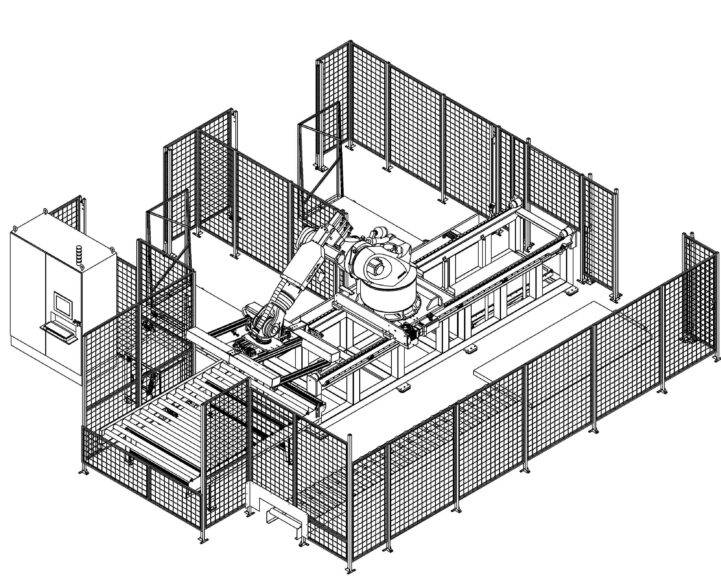

Robotized off-loading system for doors

Project goals:

- Integration of existing line with robotized off-loading and palletizing system

- Flexible solution, ideal for frequent production changeovers

Find out how Tecnodinamica stepped into this project:

Main features

- System controlled by no.1 non dedicated operator

- Powered roller conveyor for connection to the existing line

- Handling robot installed on 7th-axis

- “Martyr” panels magazine installed on the powered slide for layout optimization

- No.2 areas for the positioning of finished products

- Electrical control panel with touch screen

- Possibility of customization of loading positions and closing pressures according to the type of product

- Software integration with upstream stations

- Customized HMI interface

- Real-time process controls

- Remote assistance and process diagnostic

- Industry 4.0 requirements and integration with enterprise management systems

Indicative overall dimensions

- 8.500 x 10.000 mm (safety fences included)

Tecnodinamica activity

- Mechanical design

- Electrical design

- Software design and robot programming

- Mechanical assembly

- Wiring on board machine and electrical control panel

- In-house start-up and test

- Start-up and training at the production site