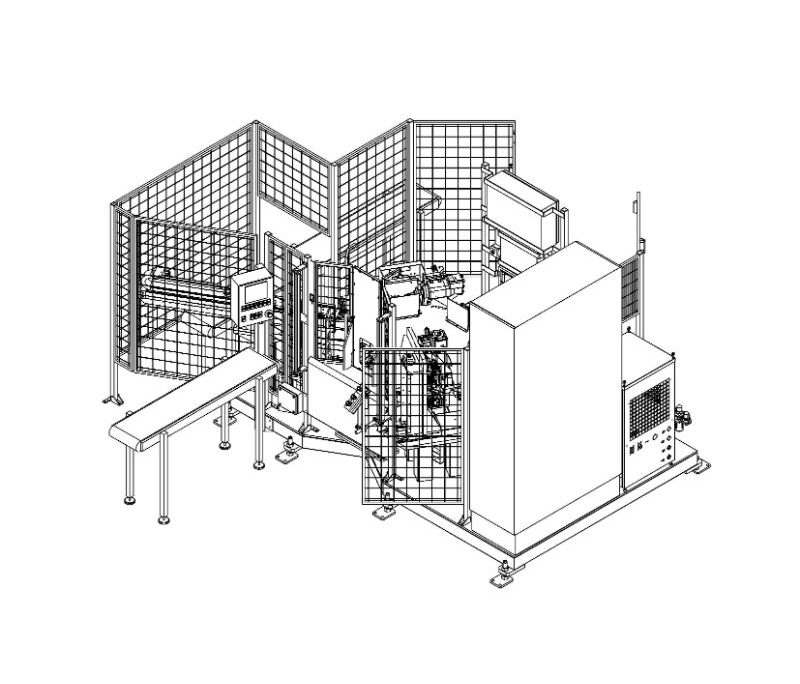

Rotary table for die-cast processing

Project goals:

Industrialization of a new product through ad-hoc system with the following requirements:

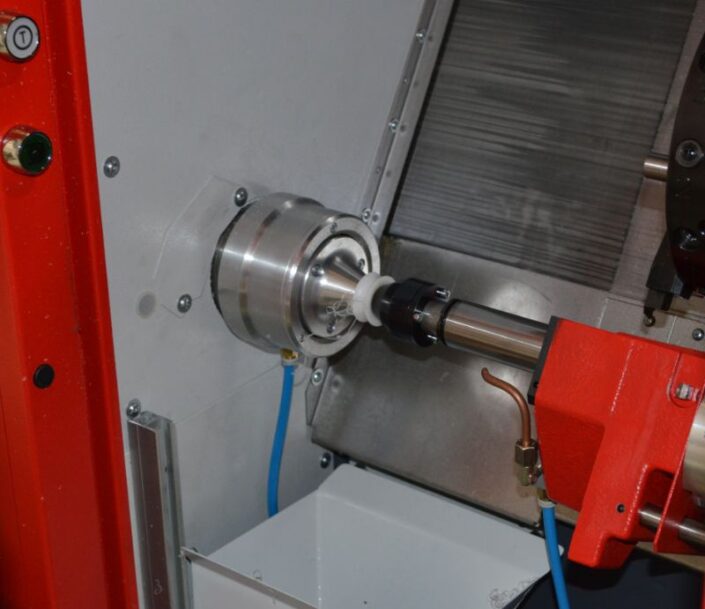

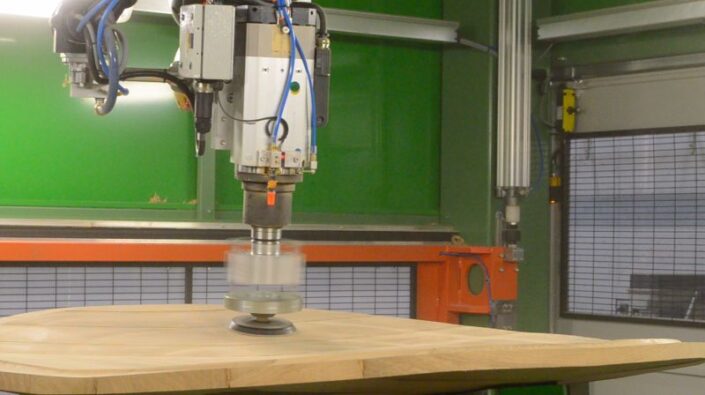

- Multiple processes (drilling, laminating, milling)

- High productivity (300 pcs/h)

- Structure and components sized for three shifts

Find out how Tecnodinamica stepped into this project:

Main features

- Machine basement made of steel with lifting points

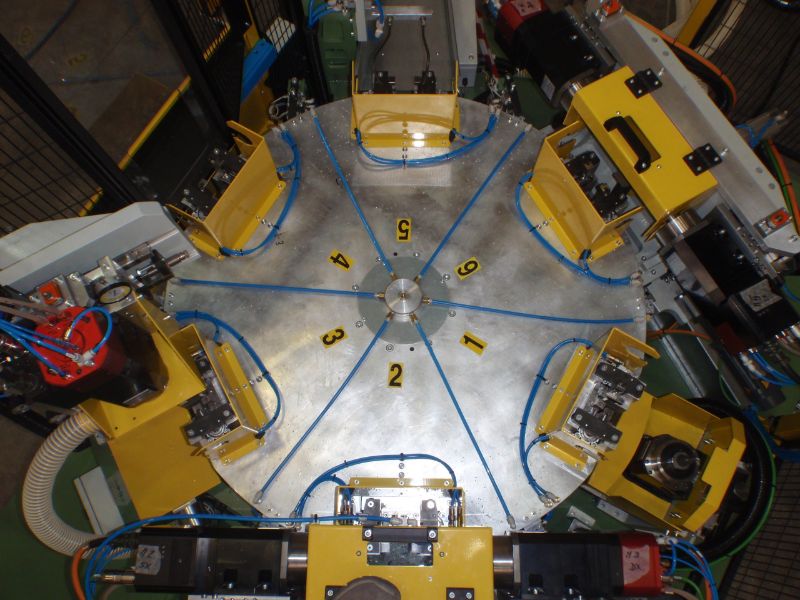

- Rotary table with no.6 workstations

- Customized templates with error free locks

- Drilling, laminating and milling units, controlled by inverter with quick tool change system

- Tool cooling and chip suction system

- Off-loading manipulator with gripper

- Electrical control panel with touch screen

- Customized HMI interface

- Real-time process controls

- Remote assistance and process diagnostic

- Industry 4.0 requirements and integration with enterprise management systems

Indicative overall dimensions

- 2.000 x 3.800 mm (safety fences included)

Tecnodinamica activity

- Mechanical design

- Electrical design

- Software design

- Mechanical assembly

- Wiring on board machine and electrical control panel

- In-house start-up and test

- Start-up and training at the production site