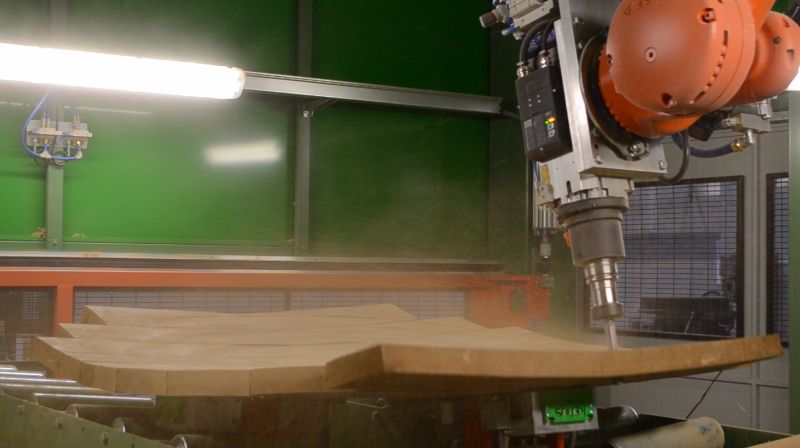

Barrel sanding machine

Project goals:

Automation of a manual process through the design and manufacture of ad hoc system:

- Design and manufacture of an automation for the automatic sanding of wooden barrels, in different shapes and dimensions, fully configurable from user interface

- Reduction of cycle times compared to market standards

- Flexible solution, ideal for frequent changes of product dimensions and shapes

Find out how Tecnodinamica stepped into this project:

Main features

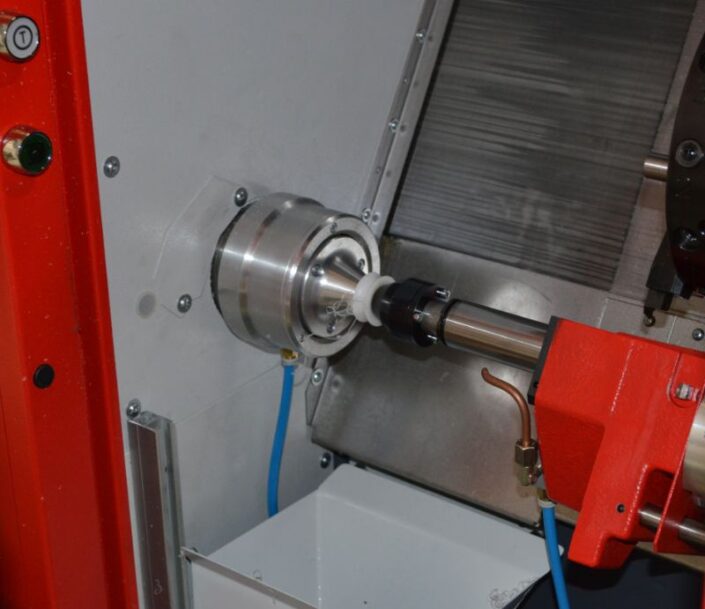

- Rotating platform provided with automatic centering unit based on the dimension of the product to be processed

- Automatic clamping unit of the barrel

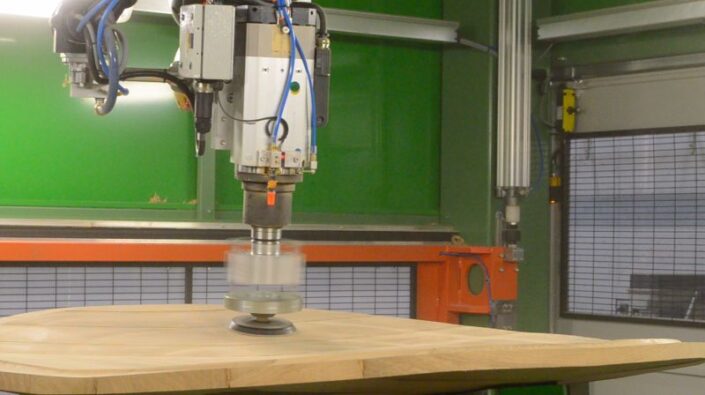

- Sanding unit, driven by electric motor, installed on two-axis handling system to match the barrel shape

- Rotating frame fit for sanding heads having different finish, driven by electric motor

- Automatic system detecting the sanding path based on the barrel shape

- Electrical control panel

- Customized CAD-CAM software for specific application

- Customized HMI interface

- Real-time process controls

- Remote assistance and process diagnostic

- Industry 4.0 requirements and integration with enterprise management systems

Indicative overall dimensions

- 7.500 x 5.000 X h. 5.200mm (except safety fences)

Tecnodinamica activity

- Mechanical design

- Electrical design

- Software design

- Mechanical assembly

- Wiring on board machine and electrical control panel

- In-house start-up and test

- Start-up and training at the production site