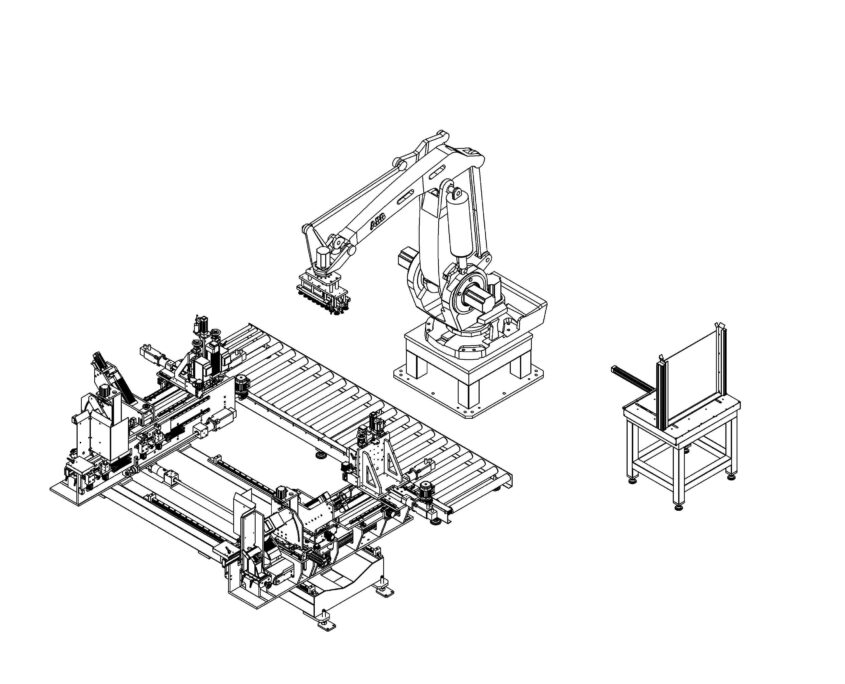

Processing system for wooden door frames

Project goals:

Automation of a manual activity:

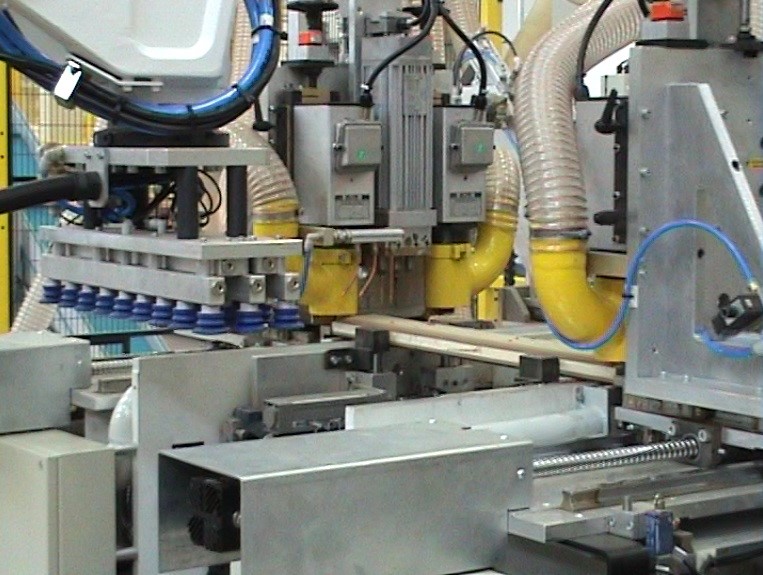

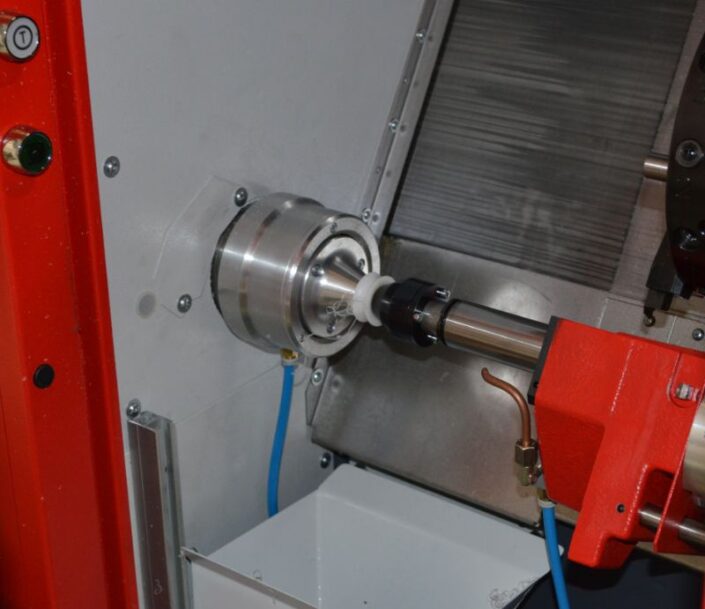

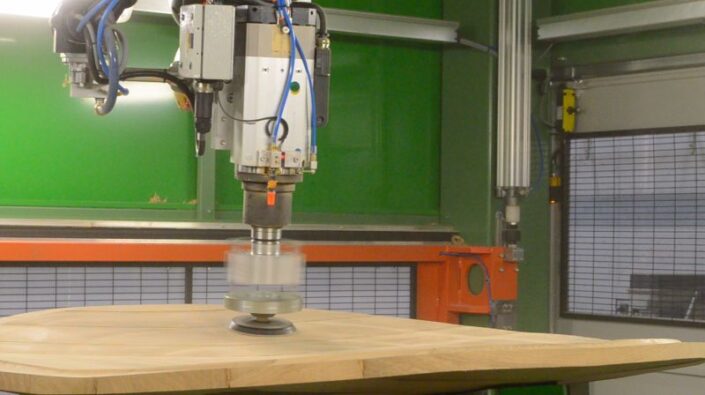

- Multiple processes with cutting, drilling and special milling units

- Flexibility for processing of different version of product

Find out how Tecnodinamica stepped into this project:

Main features

- System controlled by no.1 non dedicated operator

- Machine basement made of electro-welded steel

- Electrically adjustable frame in width

- Semi-processed products magazine

- Feeding system with adjustable speed

- Adjustable cutting, drilling, and milling units

- Wooden chip suction system

- Electrical control panel with touch screen

- Customized HMI interface

- Real-time process controls

- Remote assistance and process diagnostic

- Industry 4.0 requirements and integration with enterprise management systems

Indicative overall dimensions

- 5.900 x 6.400 mm (safety fences included)

Tecnodinamica activity

- Mechanical design

- Electrical design

- Software design

- Mechanical assembly

- Wiring on board machine and electrical control panel

- In-house start-up and test

- Start-up and training at the production site