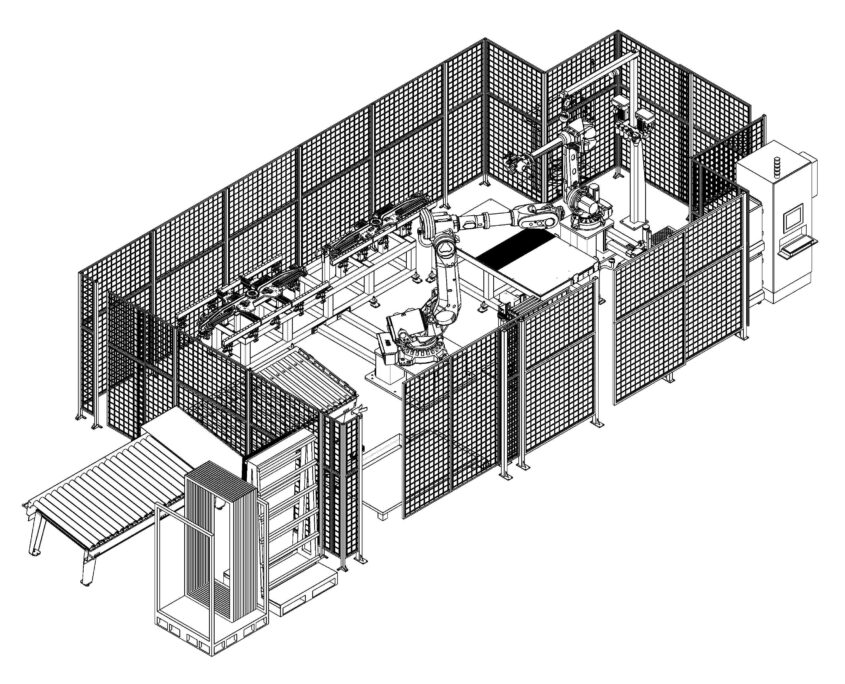

Robotized system for gluing glass

Project goals:

- Automation of a semi-automatic process through the design and manufacture of ad -hoc system

- Automatic gluing of glass elements on sheet metal frame

- Optimized operating cycle to meet with cycle times and quality requirements

- Flexible solution, ideal for frequent production changeovers

Find out how Tecnodinamica stepped into this project:

Main features

- System controlled by no.1 dedicated operator

- Powered loading roller conveyors

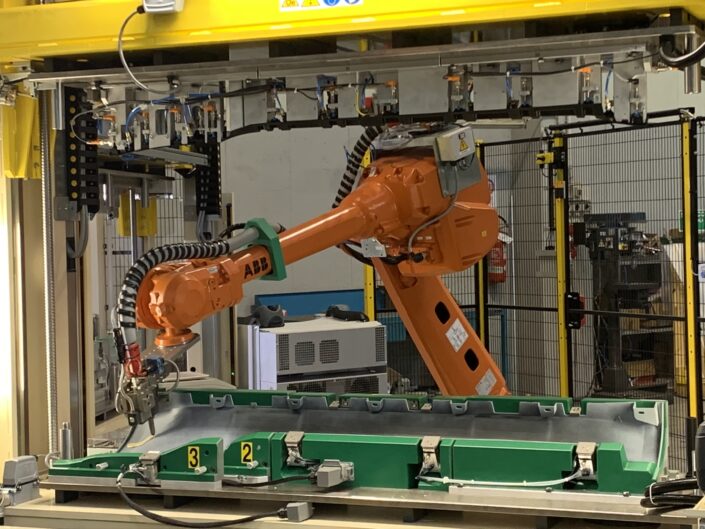

- Anthropomorphic robot for handling and assembling

- Anthropomorphic robot for cleaning and glue dispensing

- Glue dispensing system

- Gripper magazine with quick change system

- Automatic spacers dispenser for palletizing finished products

- Electrical control panel with touch screen

- Customized HMI interface

- Customizable operating cycle from user interface

- Real-time process controls

- Remote assistance and process diagnostic

- Industry 4.0 requirements and integration with enterprise management systems

Indicative overall dimensions

- 13.500 x 5.500 mm (safety fences included)

Tecnodinamica activity

- Mechanical design

- Electrical design

- Software design and robot programming

- Mechanical assembly

- Wiring on board machine and electrical control panel

- In-house start-up and test

- Start-up and training at the production site